The Army’s incredible floating repair shop kept its helicopters flying in Vietnam – and then went to the scrap heap.

Aaron Lilley Jr. was stunned when he received what amounted to a recall notice halfway through his tour in Vietnam. The ship he commanded – a one-of-a-kind floating aircraft repair station with a stellar reputation for quality work and quick turnaround – should abandon its post and head home to save money, Army Audit Agency officials wrote.

Lilley and the more than 350 machinists, mechanics and other specialists on USNS Corpus Christi Bay knew the auditors were wrong. With the ability to overhaul everything from engines to electronics and parachutes to propellers, Corpus Christi Bay kept the helicopter-dependent Army flying in Vietnam. It was faster and far less expensive than the alternative: shipping aircraft components back to the United States for repair or re-creating the ship’s sophisticated facilities on land somewhere in Vietnam.

“We could do a lot of things that had never been done before,” says Lilley, commander of the 1st Transportation Battalion (Seaborne) from June 1969 to June 1970. The ship repaired as many as 20,000 aircraft components a month and saved the military millions of dollars.

“There was nothing we couldn’t build,” adds Doug Sapp, a sheet metal fabricator and airframe repairman during Lilley’s tenure. “It was virtually a little Boeing.”

Lilley ultimately prevented the Army Audit Agency from recalling Corpus Christ Bay, and it remained off the coast of Vietnam until 1972. But the storied ship suffered a cracked hull in a tropical storm after the war and was sold for scrap in 1975, he says. Despite its success and a forceful lobbying effort by Lilley and other supporters, the Army never replaced its shipborne repair depot.

The beginning The idea of a floating aircraft maintenance shop first arose during the U.S. military’s island-hopping campaign across the South Pacific in World War II. The combat zone changed too quickly to justify land-based facilities, according to the U.S. Army Center of Military History. The concept was revived as a growing number of Army helicopters arrived in Vietnam in the early 1960s, when it became clear that the cavalry had to move by air.

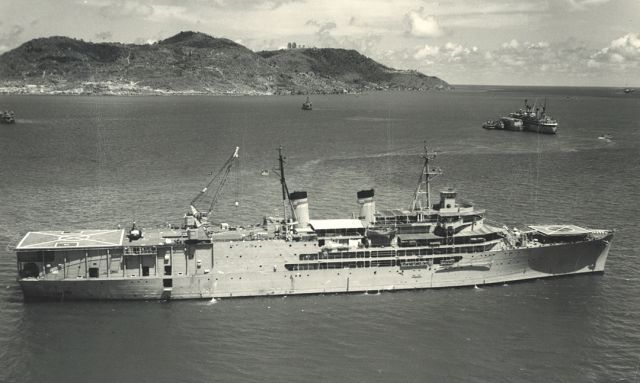

Widely respected Army aviator Col. John Sullivan oversaw conversion of USS Albemarle, a World War II Navy seaplane tender, into a sophisticated repair depot that was rechristened USNS Corpus Christi Bay. At its peak, the makeover involved 1,000 workers at the Charleston Naval Shipyard.

The result was the first Army floating aircraft maintenance facility, with 37 repair specialties including molten-salt heat-treating ovens (temperature 1,800 degrees), metal-plating, chemical and metallurgical testing, and two deck cranes for unloading helicopter engines and other heavy freight. “You name it, there was a shop for it,” says Alan Barrick, who served an 18-month tour on Corpus Christi Bay from 1969 to 1970.

“The ship provided several advantages,” adds Ed Raines, a military historian. “It concentrated all the machinery and skilled mechanics and other technicians required to keep the aircraft, both fixed-wing and rotary-wing, flying.”

A library of 180,000 blueprints made it possible for the 1st Transportation Corps to make practically any part for the aircraft components they serviced. The rest of the ship was equally impressive, with air-conditioned living quarters, dry cleaning and shoe-repair shops, a post exchange and a barber shop. There were facilities for a flight surgeon, medical staff and a dentist. But the renovated ship was so top-heavy that the military had to place five feet of concrete in the bottom of the hold to stabilize it.

Sailing and maintaining Corpus Christi Bay fell to a Merchant Marine captain and crew. The ship arrived in Vietnam in April 1966 with about 370 Army personnel running repair facilities. It was first posted to Cam Ranh Bay, then moved to Qui Nhon to be closer to the 1st Cavalry, which relied on hundreds of aircraft, from helicopters to fixed-wing spotter planes. Corpus Christi Bay did work for other units and other branches as well, Barrick says.

Dream assignment Soldiers selected to serve on Corpus Christi Bay had aircraft repair training or demonstrated aptitude for the work. Some, like Sapp, had wanted to become aircraft mechanics since childhood. All were at the top of their class. “I had the best battalion in the Army,” Lilley says. “They could do anything in the world and had no complaints.”

A ranch kid from Curlew, Wash., Sapp was drafted during his first year of college. He signed up to serve an extra year to avoid the infantry. He trained in airframe repair and sheet metal work at Fort Eustis, Va., and then received a year of additional training at the Army aircraft maintenance facility in Corpus Christi, Texas – as did most soldiers who served on the ship.

It was serendipity. Sapp headed to Vietnam in 1968 buoyed by his older brother’s promise that they would start an aircraft company when he came home from the war. But when he saw the ship where he was destined to spend the next year, his first thought was, “It looks damned small.”

Like Sapp, Jesus Perez was born to do this work. He started repairing tires in the gas station his father managed in Mercedes, Texas, when he was 9. Perez joined the Air Force after high school and was on track to become a radar operator until they discovered he was colorblind. He instead trained as an airframe repairman, patched bullet holes and

fixed other combat damage on B-26 light bombers in Korea from 1952 to 1953.

Perez joined the Army in 1958 after a four-year hiatus from the military, served with a helicopter company during his first tour in 1962 and became an airframe repair instructor. He was in charge of the engine and powertrain repair platoon during his two tours on Corpus Christi Bay in the late 1960s.

“We were the highest echelon in Army aviation in Vietnam, and we were saving the government lots of money,” Perez says. He retired from the military and enjoyed a second career with a civilian contractor that worked on airplanes for the Army, FBI and other government agencies. That sort of success was the norm among Corpus Christi Bay veterans, Perez says. “All of those kids got good jobs when they got out.”

Barrick fits that bill. He too was drafted while in college and signed up for an additional year in the Army to qualify for aviation maintenance training. Barrick got a taste of what was coming in Vietnam during his year at the Army aircraft maintenance depot in Texas, where he worked on helicopter engines, transmissions, gear boxes and everything else “from the rotor head to the tail,” he says. Part of that duty included cracking open crates that contained worn-out or damaged aircraft parts and mud, sand and smells that had hitchhiked from the war zone. Once aboard Corpus Christi Bay, Barrick primarily dealt with rotor heads and swashplates. A lot of them. “There was a constant flow of repair work,” he says.

Every piece Corpus Christi Bay’s shops worked on was restored to factory specifications. Reassembled engines and other parts were taken through the paces in one of the ship’s test cells before being returned to service.

About a dozen crew members were stationed on land. They gathered helicopter and airplane parts as they came in from combat units, boxed them up and transported them to the ship. Tom Mott was one of these “sand crabs.”

Mott had already trained as an amphibious vehicle mechanic when he was tapped to go to Vietnam in 1969. He lived at the Vung Tau airfield, loaded and unloaded trucks bearing helicopter parts, and made at least one freight run a day to Corpus Christi Bay – moored about a mile off shore – in his 15-ton amphibian. The waves made unloading the steel cans with engines, or the long boxes with rotor blades, a challenge. He tied up to a barge alongside Corpus Christi Bay. That gave the ship’s crane operator a clear view of what he was hoisting from below. And yet “the ship is rolling one way, the barge is rolling the other way, and then there’s the amphibian – the smallest of the three,” Mott says.

There were plenty of perks. To a man, those who served on the ship fondly remember the food. Navy river rats and passing helicopters made it a point to show up for drive-by repairs around lunchtime, Barrick says. Christmas dinner in 1969 made the biggest impression. There was lobster, turkey, ham and all the sides. “You’d think you were eating in a five-star restaurant,” he says. “It was really sweet compared to what many other GIs endured,” Sapp adds.

Paying forward The 1st Transportation Battalion did more than precision aircraft work and eating well. The first contingent adopted an orphanage in Cam Ranh Bay in 1966, Barrick says. And the ship’s medical staff helped local villagers after the relocation to the Vung Tau area. For example, the ship’s doctor and dentist helped arrange for a 9-year-old Vietnamese girl to have surgery to correct a congenital heart problem – an event chronicled in the September 1970 issue of the ship’s newspaper, the FanTail.

Barrick earned his FAA airframe and powerplant license after he got out of the Army, and enjoyed a 33-year civil service career that included overseeing maintenance and repair of all Army Reserve unit aircraft in a region extending from Maine to Puerto Rico. When he retired in 2002, he was working in Army logistic research and development. Separately, he rose through the ranks to aviation chief warrant officer in the Army Reserve. “I owe it all to getting drafted into the Army,” he says.

Sapp also feels fortunate to have been drafted. “It’s probably the best thing that ever happened to me,” he says. His brother made good on his promise, and the two ran an aircraft salvage and repair company for the first 12 years after he got out of the service. One of their specialties was retrofitting Piper Super Cubs for use in the Alaska bush. Today he runs a company in Omak, Wash., that sells parts for a vintage Chinese fighter/trainer popular with collectors, and continues to restore airplanes.

Like many of the men who served on the ship, he’s active in the USS Albemarle/USNS Corpus Christi Bay Reunion Association, which still includes a few veterans from the ship’s World War II service era, as well as a large contingent of Vietnam veterans. They are proud to have served on the only floating Army aircraft shop ever to go to sea.

Ken Olsen is a frequent contributor to The American Legion Magazine.

Find the USS Albemarle/USNS Corpus Christi Bay Reunion Association:

ussalbemarle-usnscorpuschristibay.org/reunion.htm

On Facebook: USNS Corpus Christi Bay Alliance

- Magazine